Titanium Electrodes for Chlor-Alkali Industry

Coating type: Ru/Ir

Precious metal content: proportion according to application

Service life: >15000 hours

Current density: <1300A/m2

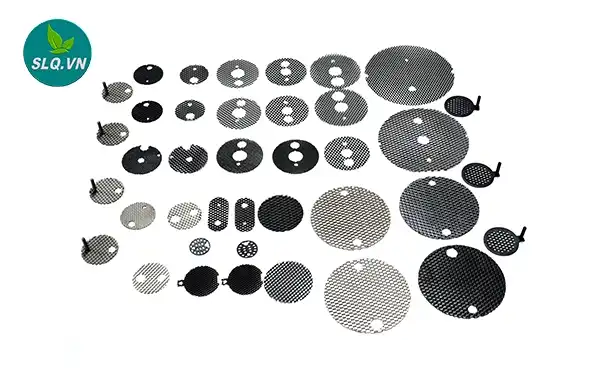

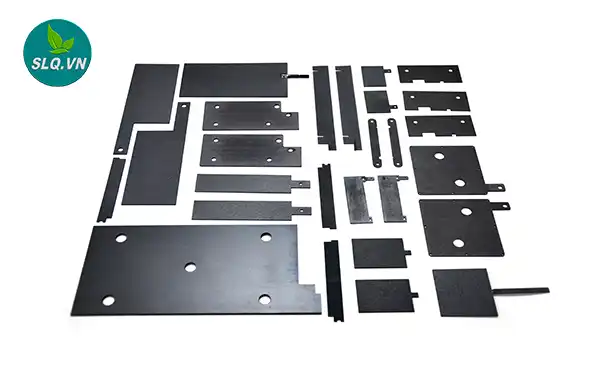

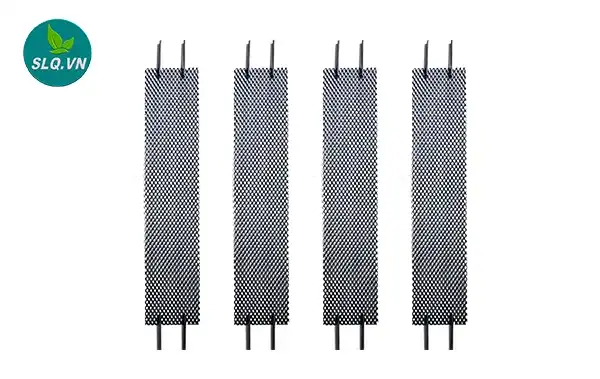

Size and shape: Customized according to your drawings or samples

Product advantages: Using our unique coating formula, the product has good electrolytic stability and high electrolysis efficiency.

1. Basic Product Details:

Titanium Electrodes for Chlor-Alkali Industry are crucial parts that are used in electrolysis processes to make hydrogen, caustic soda (sodium hydroxide), and chlorine. To guarantee superior performance and long-term durability in harsh chemical environments, these electrodes are manufactured from titanium of the highest possible quality. Titanium cathodes are basic to the chlor-salt industry, where the electrolysis of brackish water (sodium chloride arrangement) produces chlorine, scathing pop (sodium hydroxide), and hydrogen. These electrodes, which are typically covered in precious metals like platinum, iridium, or mixed metal oxides, ensure that electrolysis is effective, consumes little energy, and produces products of high purity. For continuous operation in chlor-alkali plants, their corrosion resistance and stability in harsh electrolytic environments are essential. It support global industrial infrastructure and the production of essential goods by enabling sustainable production processes and contributing to various industries that rely on chlorine and caustic soda, such as chemical manufacturing, pulp and paper, and water treatment.

2. Product Standards:

Our mmo coated titanium anodes conform to international standards such as ASTM B265 for titanium materials and ASTM B338 for seamless and welded titanium tubes.

3. Basic Parameters:

| Parameter | Value |

|---|---|

| Material | Titanium |

| Coating Material | Ruthenium, Iridium, Platinum (optional) |

| Diameter | 3 inches to 30 inches |

| Length | Customizable |

| Coating Thickness | 6-8 microns |

| Max Operating Voltage | 4.5 volts |

| Max Current Density | 2000 A/m2 |

4. Product Attributes:

- Corrosion resistance: Titanium Electrode offer exceptional corrosion resistance, ensuring longevity in aggressive chloride environments.

- High conductivity: Efficient electrical conductivity enables optimal electrolysis performance.

- Customizability: Available in various sizes and configurations to meet specific application requirements.

- Stability: Provides stable operation over extended periods, minimizing downtime and maintenance costs.

5. Product Functions:

Titanium Electrodes for Chlor-Alkali Industry facilitate the electrolysis process by transferring electrical current through the electrolyte solution to produce chlorine gas, hydrogen gas, and caustic soda.They are pivotal in the chlor-alkali industry, facilitating critical functions in the electrolysis process. As catalysts, they initiate the decomposition of brine into chlorine gas, hydrogen gas, and caustic soda. At the cathode, it promote the reduction of sodium ions to produce caustic soda and hydrogen gas. Simultaneously, at the anode, they facilitate the oxidation of chloride ions to yield chlorine gas. Beyond their catalytic role, they offer unparalleled corrosion resistance, ensuring prolonged service life and sustained efficiency in the harsh chemical environment of electrolysis cells. Their reliability and durability are integral to the consistent production of essential industrial chemicals.

6. Features:

- Robust construction for durability

- Low maintenance requirements

- High efficiency in chlorine production

- Suitable for both diaphragm and membrane electrolysis cells

7. Advantages and Highlights:

- Superior corrosion resistance compared to conventional electrode materials such as graphite or steel.

- Enhanced performance and longevity result in cost savings over the lifespan of the electrodes.

- Customization options available to meet specific operational needs.

8. Application Areas:

It find widespread use in chlor-alkali plants, water treatment facilities, electrolytic synthesis, and other industrial processes requiring electrolysis.

9. OEM Services:

We offer OEM services to tailor titanium electrode according to clients' specifications, including custom sizes, coatings, and configurations.

10.Certifications:

11. FAQs:

Q: Are they suitable for high-temperature electrolysis? A: Yes, mmo coated titanium anodes can withstand elevated temperatures encountered in electrolysis processes.

Q: Can this product be used in seawater electrolysis? A: Absolutely, titanium's excellent corrosion resistance makes it ideal for seawater electrolysis applications.

Properties and Details of the Material:

Titanium cathodes are commonly produced using Grade 1 or Grade 2 titanium, known for their phenomenal erosion obstruction and biocompatibility. Furthermore, coatings like ruthenium, iridium, or platinum can be applied to improve conductivity and strength in unambiguous electrolysis conditions.

Introduction of Shellaiqi Titanium Industry Co., Ltd.:

Shellaiqi Titanium Industry Co., Ltd. is a professional manufacturer and supplier of it. We pride ourselves on delivering high-quality products that meet international standards and exceed customer expectations. With comprehensive certifications, complete test reports, and support for OEM requirements, we ensure customer satisfaction. For inquiries or to order Titanium Electrodes for Chlor-Alkali Industry, please contact us at fujianuo@shelllaiqi.com.

hotTags:Titanium Electrodes for Chlor-Alkali Industry,supplier,wholesale,factory,manufacturer,OEM,ODM,trader,for sale,in stock,free sample,buy.