Product

Titanium Spring Pad

Size: M2-M64

Standard: DIN125 DIN127

Material: GR1/GR2/GR3/GR5

Surface Treatment: Anodizing, polishing,black oxide

Advantage: OEM / customized service provided

Application: Industry; medical; car; motorcycles; bicycles

Feature: Protection connection; corrosion resistance; low density

External Hexagonal Titanium Screws

Titanium Grade: Gr2 / Gr7

Size: Customized as your drawing or sample request

Features: Acid and alkali resistance, anti-corrosion, excellent mechanical strength etc.

Applications: Home Improvement, Sport Equipments, Motocycle DIY, Frames, Disc Brakes, Fasteners, Pipes, Car and Bicycle Modification

Surface treatment: Polished,Anodizing, Black oxide

Oxygen-Evolving Titanium Electrode

Base material: Gr1

Coating type: Ru/Ir

Precious metal content: proportion according to application

Service life: >15000 hours

Current density: <1300A/m2

Size and shape: Customized according to your drawings or samples

Product advantages: Using our unique coating formula, the product has good electrolytic stability and high electrolysis efficiency.

Sintered Platinum-Titanium Anode

Base material: Gr1

Coating Type: Platinum

Coating thickness: 0.2~20μm

Service life: >15000 hours

Output current: 300A-500A/m2

Usage environment: PH1-13

Size and shape: Customized according to your drawings or samples

Application areas: Household appliances, disinfection electrocatalysis, water treatment, etc.

platinum coated titanium electrodes

Base material: Gr1

Coating Type: Platinum

Service life: >15000 hours

Coating thickness: 0.2~20μm

Output current: 300A-500A/m2

Usage environment: PH1-13

Size and shape: customized according to your drawings or samples

Tantalum Plate

Purity: 99.95% min

Grade: R05200, R05400, R05252, RO5255, R05240

Standard : ASTM B365

Size: Dia(1~25)xMax3000mm

Condition

1.Hot-rolled/Cold-rolled

2.Alkaline Cleaning

3.Electrolytic Polish

4.Machining, grinding

5.Stress relief annealing

Tantalum Alloy Rod

Material: 99.6% tantalum

Color: nickel white

Standard: ASTM B365 ASTM B780

Grade: R05400 R05200, R05252, R05255, R05240

Length: 3.0mm~150mm

Features: Good ductility and toughness , Low coefficient of thermal expansion, Good corrosion resistance

Used: Electrical industry, tool bit and aiguille, modern medicine, metallurgy, aviation.

Magnesium granules

Appearance:Silver white

Shape: Granular

Model Standard:ASTM Standard

Application:Magnesium is an indispensable non-ferrous metal powder in the current high-tech field, which is widely used in aviation, aerospace, automobile, petroleum, chemical industry, medicine, metallurgy and other industries.

Pure Magnesium Powder

Magnesium Specification: AZ91D ,AM50A , AM60B

Size (mm): 1.2*1.2*4

Magnesium Nanoparticles Mg APS: 20-300mesh

Magnesium Nanoparticles Mg Purity: 99.9% (metal basis)

Magnesium Nanoparticles Mg Morphology: spherical

Magnesium Nanoparticles SSA: 2.5 - 5m2/g

Magnesium Melting point/Melting range: 650°C

Magnesium Boiling point/Boiling range: 1100°C

Magnesium Density at 20°C: 1.738 g/cm³

Magnesium Alloy Rod

Shape: Round

Standard:AMS/ASTM/JIS/BS/ISO

Brand:AZ31B/ZK60A/AZ91D/AZ61A/AZ40M/AZ80A

Dimension:φ3-φ130mm*3000mm(Customized)

Magnesium Plate

Size Range: Sheet: thickness from 0.5mm to 7mm; Max. width is 600mm; Max. length is 1200mm;

Chemical Composition: Al: 2.5-3.5%; Zn: 0.7-1.3%; Mn: 0.20 – 1.0%; Mg: Balance

Physical Properties:

Density: 1.78g/cm3

Coefficient of thermal expansion: 26.8 x 10-6K-1

Specific heat: 1040 Jkg-1k-1

Thermal conductivity: 76.9Wm-1k-1

Electrical resistivity: 92nΩm

Modulus of elasticity: 45 x 109Pa

Poissons ratio: 0.35

Melting range: 566 - 632°C

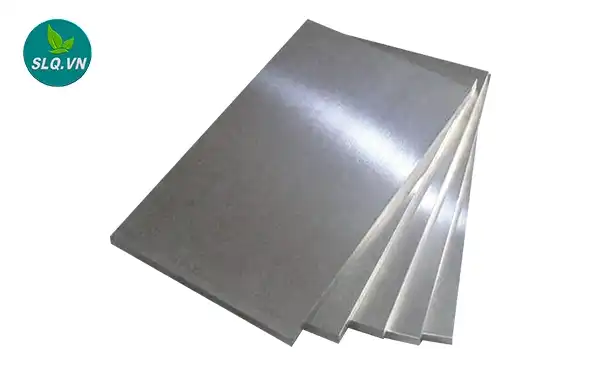

Pure Molybdenum Plate

Material: Mo1,Mo2,TZM

Standard: ASTMB386, GB/T 3877

Application: Construction of furnace tooling and parts and as a feed stock for the fabrication of parts for the electronics and semiconductor industries.

Processing: Powdering, molding, sintering,machining

Feature: High strength, long service life, good flatness

Surface: Polishing/ground, caustic washing